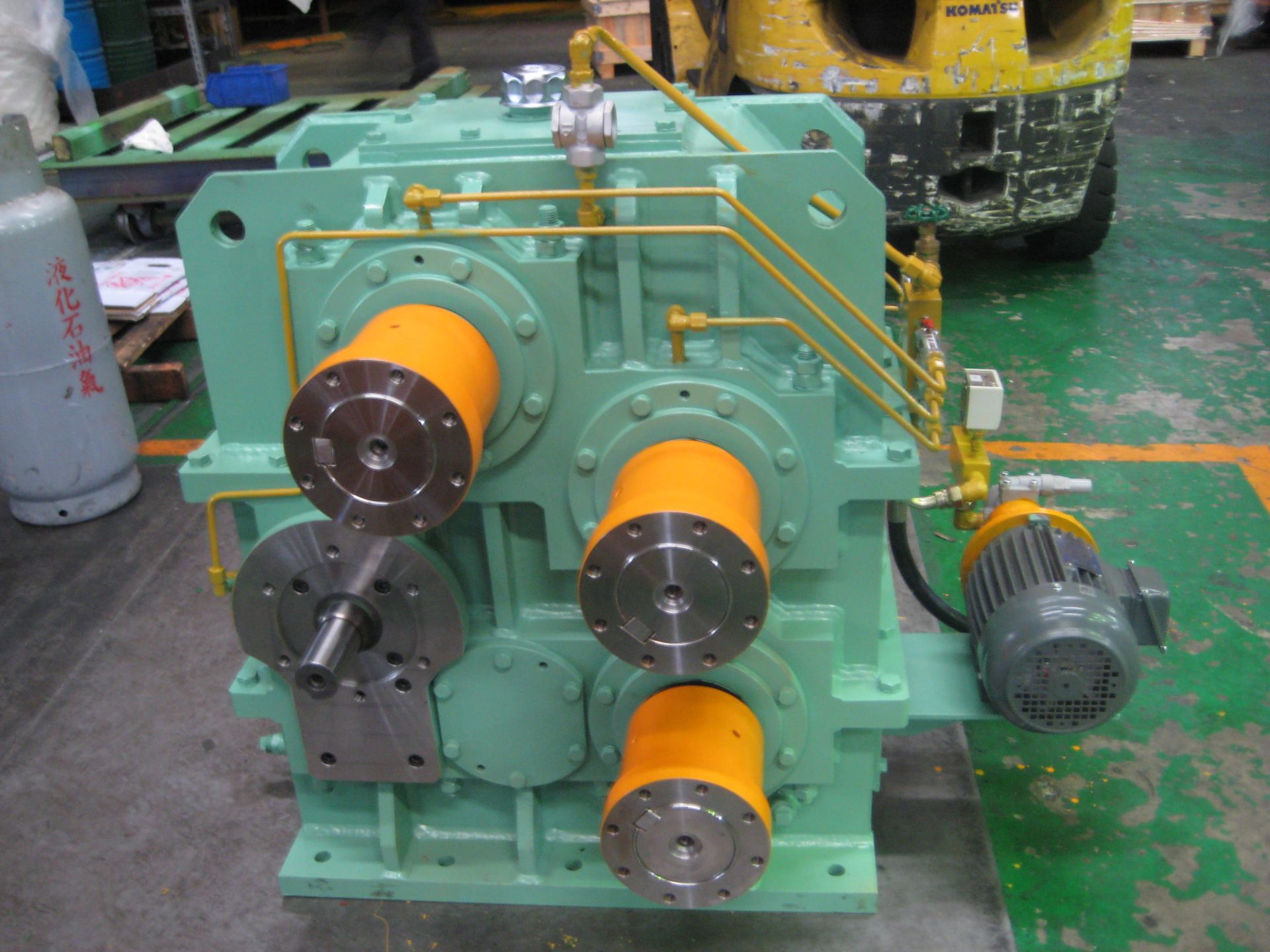

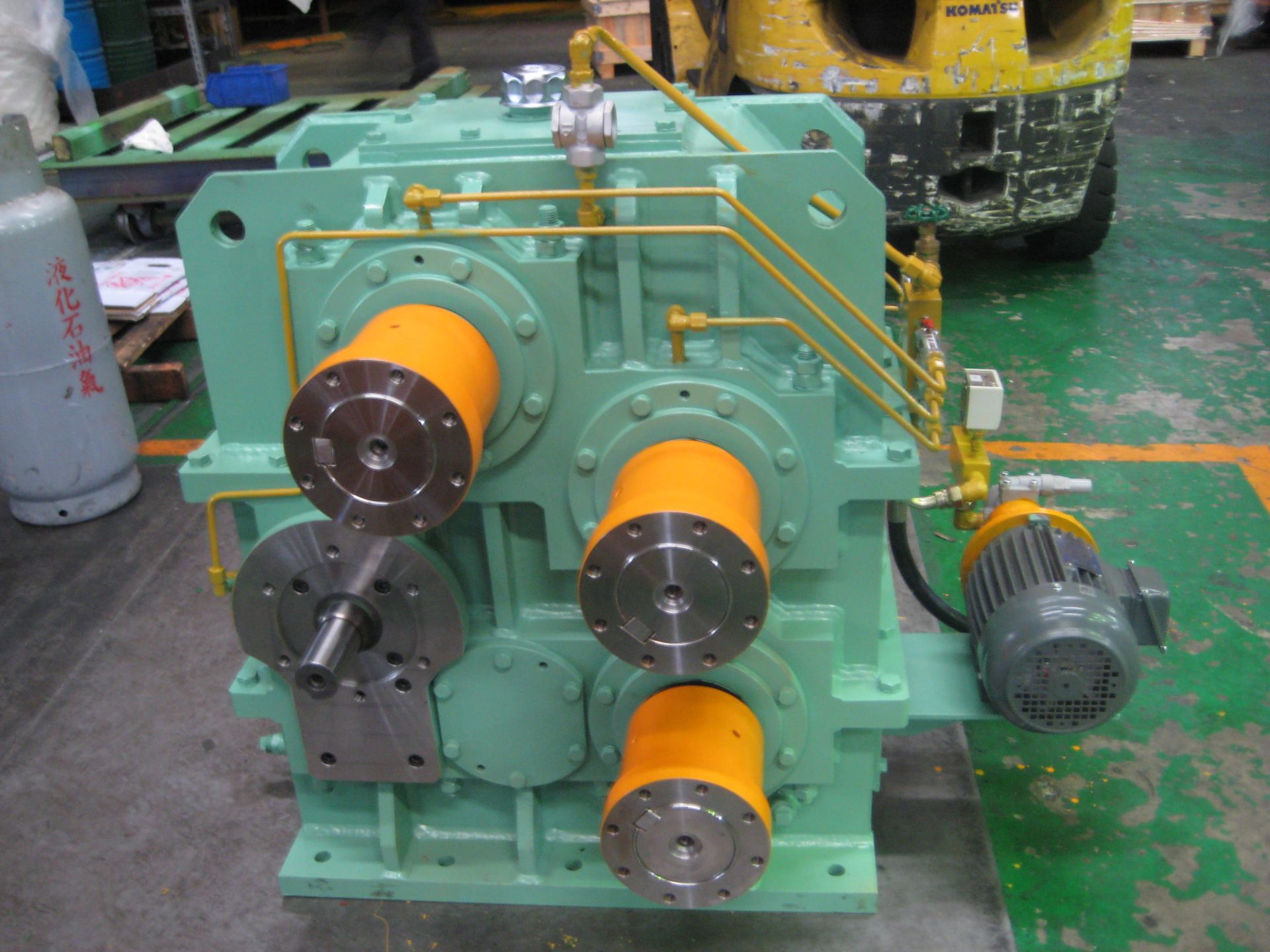

Reference Model

Gear boxes/reducers play a core role in the rubber and plastic industries by regulating speed and torque in processing equipment such as extruders, mixers, calenders, and injection molding machines. To ensure maximum efficiency and precision during operation, it is crucial to have precision-engineered gear boxes/reducers with robust construction and high-quality materials capable of withstanding heavy loads and continuous operation.

TIEN YI, a reputable manufacturer with over four decades of experience, recognizes the significance of providing top-quality gearboxes designed specifically for the unique challenges faced in the rubber and plastics industries. Offering an extensive range of OEM/ODM and private-label products, including gearboxes/reducers, gear couplings, disc couplings, universal joints, and custom precision gears, TIEN YI caters to the specific needs of this industry.

Gear Boxes/reducers play vital roles in various machinery within the rubber and plastic industry. TYGear-Gearboxes are extensively employed in diverse applications, including:

High-quality gear boxes/reducers possess essential features for efficient operation. For optimal performance, look for gear reducers that offer precise speed control and can provide sufficient torque for demanding mixing and extrusion processes. Gear boxes/reducers with energy-efficient gear ratios contribute to cost savings and eco-friendly operations.

When selecting gear boxes/reducers for the rubber & plastic industries, focus on robust construction to ensure gearboxes can withstand heavy loads and continuous operation. Temperature resistance guarantees reliable performance under elevated temperature conditions, while low maintenance requirements minimize downtime and enhance productivity.

With over four decades of experience, TYGear understands the unique requirements of the rubber and plastic industries.

We offer an extensive range of OEM/ODM and private label gear reducers designed to meet the specific needs of this industry.

Successful Case